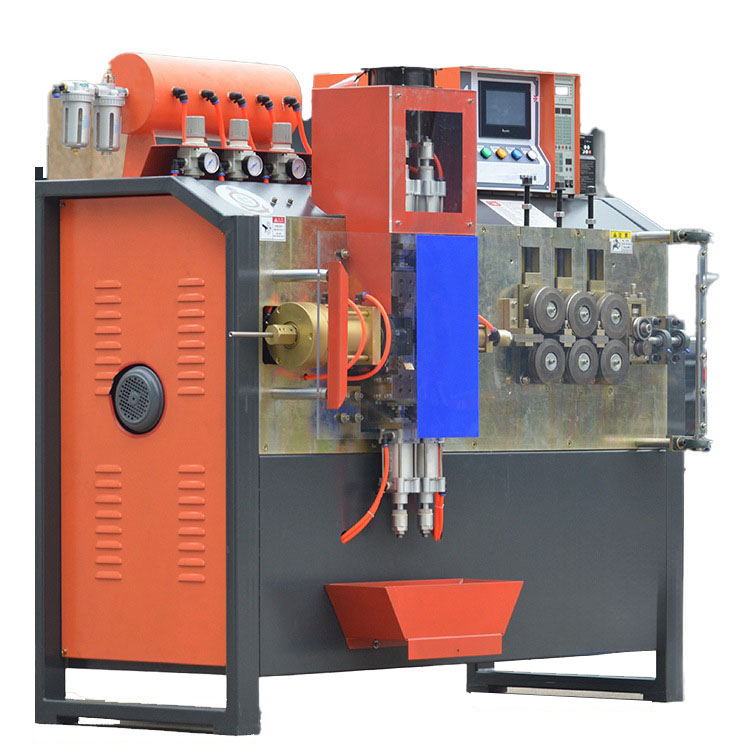

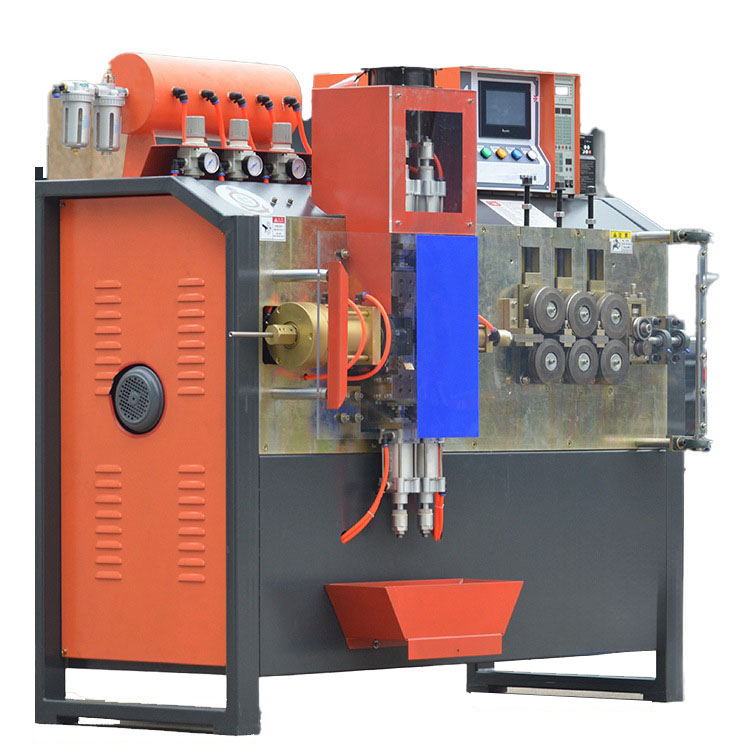

Parameter Model WPM-CF

Input voltage 380 V/50Hz or 220V/50HZ

Rated power 40KW

Fuse wire diameter ≤Φ12 mm

Efficiency (fusing working time does not include preparation working time such as taking the workpiece) approx. 30 times/min Wire rope fusing diameter specification 2-6.5mm (40AB) 2-10mm (80AB)

Pressurized mode Air Pressure

Delivery time 10 business days. 8MM automatic fuse breaker in stock, other specifications of models and accessories need to be customized.

Cylinder stroke 25MM

Fuse back head Flat head

Controller Industrial control system + fuse breaker system